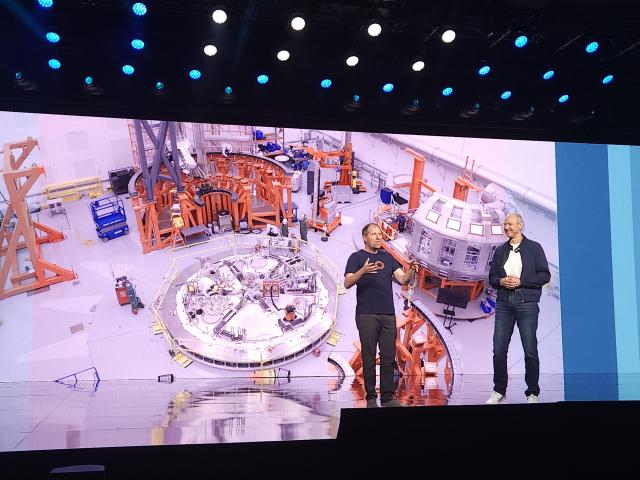

Roland Busch, CEO of Siemens (right), and Bob Mumgaard, CEO of Commonwealth Fusion Systems (left), speak during a keynote session on Jan. 6 at the Venetian Hotel in Las Vegas, discussing partnership examples in which AI is driving large-scale industrial transformation. The image of a fusion power plant shown on the screen behind them depicts a virtual environment built using digital twin technology. AJP Park Sae-jin

Roland Busch, CEO of Siemens (right), and Bob Mumgaard, CEO of Commonwealth Fusion Systems (left), speak during a keynote session on Jan. 6 at the Venetian Hotel in Las Vegas, discussing partnership examples in which AI is driving large-scale industrial transformation. The image of a fusion power plant shown on the screen behind them depicts a virtual environment built using digital twin technology. AJP Park Sae-jin LAS VEGAS (AJP) - At CES 2026, Siemens outlined a vision for an AI-driven restructuring of global industry, arguing that artificial intelligence is moving beyond software applications to become a foundational element of physical systems across manufacturing, logistics, energy, and infrastructure. At the center of that strategy is digital twin technology, which the company presented as the key mechanism for applying AI safely and reliably in the real world.

Siemens framed digital twins not as visualization tools but as operational replicas of physical systems. By integrating design data, operating conditions, physical laws, and real-time sensor information, digital twins allow companies to test and validate thousands of scenarios before assets are built or deployed. According to Siemens, this capability is critical in industries where errors carry high costs or safety risks, and where traditional trial-and-error approaches are impractical.

Roland Busch, president and CEO of Siemens, emphasized those constraints during his keynote on Jan. 6 at the Venetian Hotel in Las Vegas. “In the industrial world, AI hallucinations are not acceptable,” Busch said. “AI that enters physical systems is no longer just a feature. It becomes a force with direct real-world impact.” Reliability and safety, he added, are prerequisites for deploying AI at industrial scale, making digital twins a necessary foundation rather than an optional enhancement.

The company used nuclear fusion energy as its most prominent example of that approach in practice. Siemens highlighted its collaboration with Commonwealth Fusion Systems, a U.S.-based fusion startup, to demonstrate how digital twins can accelerate development in fields defined by extreme complexity and risk. Fusion reactors require precise coordination among magnets, cooling systems, and power controls, where even small design flaws can have serious consequences.

Busch said such systems leave no room for real-world experimentation. “In these environments, trial and error in the physical world is not an option,” he said. Every design choice and operating condition must be validated in a digital twin, where physical behavior can be simulated repeatedly before any hardware is built. Siemens argued that this process shortens research and development timelines while reducing the likelihood of costly or dangerous failures.

Siemens positioned the fusion work as a template rather than a one-off case. The same digital twin framework, the company said, can be applied to factories, logistics centers, and power grids. By combining virtual replicas of these systems with AI, operators can anticipate disruptions, optimize performance, and adjust operations in real time. Busch described this shift as a move away from reacting to problems after they occur toward designing systems that act proactively.

Partnerships with major technology firms were presented as critical to making that model work at scale. Siemens pointed to its collaborations with NVIDIA and Microsoft as efforts to link AI-accelerated computing, simulation technologies, and industrial AI copilots into a single workflow spanning design, manufacturing, and operations. The company also showcased hands-free, smart-glasses-based guidance for shop-floor workers, positioning it as a way to improve safety and productivity while narrowing skill gaps.

At CES 2026, Siemens focused less on individual product announcements than on defining how AI can be embedded into physical systems without compromising safety or reliability. By using fusion reactors as a proving ground for digital twin technology, the company sought to show how AI-driven simulation can reduce risk and compress development cycles in the most demanding industrial environments, before extending that same logic across manufacturing, logistics, energy, and infrastructure.

Park Sae-jin Reporter swatchsjp@ajunews.com

![[포토] 폭설에 밤 늦게까지 도로 마비](https://image.ajunews.com/content/image/2025/12/05/20251205000920610800.jpg)

![[포토] 예지원, 전통과 현대가 공존한 화보 공개](https://image.ajunews.com/content/image/2025/10/09/20251009182431778689.jpg)

![[포토]두산 안재석, 관중석 들썩이게 한 끝내기 2루타](https://file.sportsseoul.com/news/cms/2025/08/28/news-p.v1.20250828.1a1c4d0be7434f6b80434dced03368c0_P1.jpg)

![블랙핑크 제니, 매력이 넘쳐! [포토]](https://file.sportsseoul.com/news/cms/2025/09/05/news-p.v1.20250905.c5a971a36b494f9fb24aea8cccf6816f_P1.jpg)

![[작아진 호랑이③] 9위 추락 시 KBO 최초…승리의 여신 떠난 자리, KIA를 덮친 '우승 징크스'](http://www.sportsworldi.com/content/image/2025/09/04/20250904518238.jpg)

![블랙핑크 제니, 최강매력! [포토]](https://file.sportsseoul.com/news/cms/2025/09/05/news-p.v1.20250905.ed1b2684d2d64e359332640e38dac841_P1.jpg)

![[포토]첫 타석부터 안타 치는 LG 문성주](https://file.sportsseoul.com/news/cms/2025/09/02/news-p.v1.20250902.8962276ed11c468c90062ee85072fa38_P1.jpg)

![[포토] 국회 예결위 참석하는 김민석 총리](https://cphoto.asiae.co.kr/listimg_link.php?idx=2&no=2025110710410898931_1762479667.jpg)

![[포토] 발표하는 김정수 삼양식품 부회장](https://image.ajunews.com/content/image/2025/11/03/20251103114206916880.jpg)

![[포토] 박지현 '아름다운 미모'](http://www.segye.com/content/image/2025/11/19/20251119519369.jpg)

![[포토] 김고은 '단발 여신'](http://www.segye.com/content/image/2025/09/05/20250905507236.jpg)

![[포토] 키스오브라이프 하늘 '완벽한 미모'](http://www.segye.com/content/image/2025/09/05/20250905504457.jpg)

![[포토] 알리익스프레스, 광군제 앞두고 팝업스토어 오픈](https://cphoto.asiae.co.kr/listimg_link.php?idx=2&no=2025110714160199219_1762492560.jpg)

![[포토] '삼양1963 런칭 쇼케이스'](https://image.ajunews.com/content/image/2025/11/03/20251103114008977281.jpg)

![[포토] 언론 현업단체, "시민피해구제 확대 찬성, 권력감시 약화 반대"](https://image.ajunews.com/content/image/2025/09/05/20250905123135571578.jpg)

![[포토] 박지현 '순백의 여신'](http://www.segye.com/content/image/2025/09/05/20250905507414.jpg)

![[포토] 김고은 '상연 생각에 눈물이 흘러'](http://www.segye.com/content/image/2025/09/05/20250905507613.jpg)

![[포토]끝내기 안타의 기쁨을 만끽하는 두산 안재석](https://file.sportsseoul.com/news/cms/2025/08/28/news-p.v1.20250828.0df70b9fa54d4610990f1b34c08c6a63_P1.jpg)

![[포토] 한샘, '플래그십 부산센텀' 리뉴얼 오픈](https://image.ajunews.com/content/image/2025/10/31/20251031142544910604.jpg)

![[포토] 아이들 소연 '매력적인 눈빛'](http://www.segye.com/content/image/2025/09/12/20250912508492.jpg)

![[포토]두산 안재석, 연장 승부를 끝내는 2루타](https://file.sportsseoul.com/news/cms/2025/08/28/news-p.v1.20250828.b12bc405ed464d9db2c3d324c2491a1d_P1.jpg)

![[포토] 키스오브라이프 쥴리 '단발 여신'](http://www.segye.com/content/image/2025/09/05/20250905504358.jpg)

![[포토] 아홉 '신나는 컴백 무대'](http://www.segye.com/content/image/2025/11/04/20251104514134.jpg)